Scaffolding for Beginners: Recognizing the Essentials

5 Essential Safety Tips for Scaffolding Operations ==================================================

Proper training is necessary, covering scaffold hazards, fall defense, and setting up procedures. Regular evaluations assure safety and security and structural integrity. Personal safety devices (PPE) safeguards workers from hazards with appropriate suitable and material choices. Safe scaffolding by securely anchoring and checking weather. Adherence to fill restrictions is crucial; distribute weight uniformly, know capacity, and check often. Implementing these five tips is vital to a risk-free scaffolding operation. scaffolding erection

Appropriate Training

Correct training is essential for ensuring the safety and security and performance of scaffolding procedures. Educating techniques play a crucial duty in equipping employees with the necessary skills to set up, take apart, and work on scaffolding structures. These strategies might include hands-on demos, class instruction, and substitute circumstances to prepare workers for real-world scenarios they might experience at work. In addition, qualification needs guarantee that employees have satisfied specific requirements and have the understanding and proficiency needed to function safely on scaffolding.

To satisfy qualification requirements, employees might need to finish an official training program that covers topics such as scaffold risks, fall security, and proper assembly treatments. This training helps employees understand the threats connected with scaffolding job and instructs them exactly how to minimize these dangers successfully. By assuring that workers are effectively trained and accredited, employers can promote a society of safety and security and lower the possibility of crashes or injuries on scaffolding websites.

Regular Evaluations

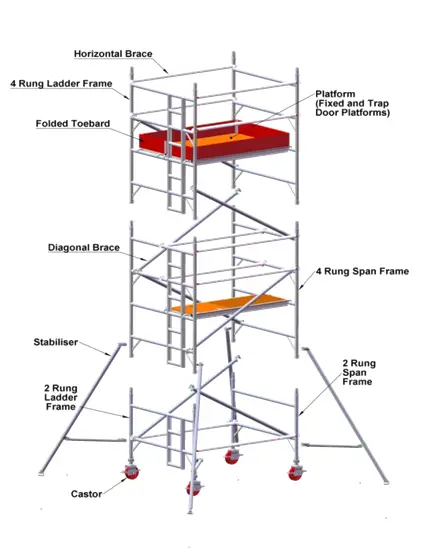

Carrying out normal inspections is vital for ensuring the continuous safety and security and structural honesty of scaffolding systems. Inspections ought to be carried out by experienced personnel complying with a recognized assessment checklist. https://southwarkscaffolding.co.uk This list should include products such as checking for any type of indications of damage, making certain all connections are secure, validating the plumb and level of the scaffolding, and validating the proper setup of guardrails and toe boards.

Along with routine examinations, it is important to have a structured upkeep timetable in place. This schedule ought to outline details upkeep jobs, such as tightening screws, replacing used parts, and resolving any kind of deterioration. By adhering to a maintenance routine, possible issues can be determined and remedied immediately, lowering the threat of crashes or architectural failures.

Routine evaluations and upkeep not just enhance safety however likewise extend the life-span of scaffolding systems. By proactively addressing any concerns, scaffolding can remain to offer a risk-free workplace for workers at elevations.

Use Individual Protective Tools (PPE)

To assure the safety and security of workers on scaffolding systems, the utilization of ideal Individual Safety Devices (PPE) is essential. PPE plays an essential role in guarding employees from possible hazards that they may come across throughout scaffolding operations. Guaranteeing that PPE is properly fitted is key to maximize its protective capacities. Uncomfortable devices can compromise safety by minimizing its performance in protecting workers from drops or various other threats. Therefore, workers have to be educated to choose PPE that fits them properly to maintain the best defense levels.

Furthermore, the choice of materials for PPE is similarly crucial. Premium products can improve longevity and convenience, motivating workers to use their protective equipment consistently. When selecting PPE, aspects such as breathability, versatility, and weight ought to be taken into consideration to ensure that the devices does not prevent employees' movements or cause discomfort. By prioritizing appropriate fit and product choices in Individual Safety Tools, employers can reduce the risks associated with scaffolding procedures and promote a much safer work environment for their staff members.

Secure the Scaffolding

Preserving the security and stability of the scaffolding framework is important for the safety and security of workers and the success of building tasks. To protect the scaffolding effectively, anchor factors must be securely established to the building or framework. These anchor factors supply the required support to support the security of the scaffolding. Normal checks and examinations of these support factors must be carried out to guarantee they remain in great condition and can bear the weight of the scaffold and employees.

In addition, weather conditions play a pivotal role in the security of the scaffolding. High winds, rain, or snow can endanger the stability of the structure, bring about potential crashes. It is essential to keep track of weather prediction and take necessary preventative measures to safeguard the scaffolding throughout unfavorable weather conditions.

Additionally, tie-offs need to be made use of to additionally enhance the stability of the scaffolding. Workers must be appropriately connected off to the framework to stop falls and guarantee their safety while operating at heights. By adhering to these practices, the scaffolding can be safely in place, reducing the risk of crashes and injuries on the building and construction site.

Abide By Lots Restrictions

Adherence to pack restrictions is essential in ensuring the structural stability and safety and security of scaffolding operations. Failing to follow defined weight capabilities can lead to disastrous accidents. To ensure safe scaffolding methods, take into consideration the following:

Load Distribution: Disperse the weight equally across the scaffolding structure. Focusing weight on one section can bring about instability and possible collapse.

Weight Capability: Constantly recognize the weight capacity of the scaffolding system being utilized. Surpassing this limitation can jeopardize the whole framework.

Routine Evaluations: Conduct constant evaluations to look for any type of indicators of overloading or structural stress. Resolve any type of issues promptly.

Training and Communication: Make sure all workers are educated on tons limitations and understand the relevance of adhering to them. Motivate open interaction relating to any concerns about weight distribution.

Often Asked Concerns

What Should Be Carried out in the Occasion of Unforeseen Serious Climate Condition While Servicing Scaffolding?

In the event of unexpected serious weather while dealing with scaffolding, prioritize safety and security preventative measures by keeping track of climate updates, developing clear communication channels, and executing emergency reaction and discharge treatments to ensure the wellness of all personnel entailed.

Exactly How Usually Should Scaffolding Materials Be Changed or Upgraded to Make Certain Safety?

Normal evaluation has to be executed to establish the state of scaffolding products. Replacement schedule and safety upgrades must straighten with manufacturer suggestions and industry requirements. Maintenance requirements are essential to assure the safety and stability of scaffolding structures.

Are There Specific Regulations or Guidelines for Working With Scaffolding Near Power Lines or Electrical Sources?

Safety safety measures should be purely followed when working with scaffolding near high-voltage line or electrical resources to avoid electric threats. Laws commonly mandate certain distances that need to be maintained between scaffolding and high-voltage line for employee safety.

What Tips Should Be Required To Avoid Unauthorized Access to Scaffolding When Not in Use?

To stop unapproved accessibility to scaffolding when not being used, strict access control actions must be enforced. Implement security protocols such as lockout/tagout treatments, physical obstacles, and normal assessments to hinder unauthorized entrance and guarantee security precautions are satisfied.

Just How Can Employees Interact Effectively While Working With Separate Degrees of Scaffolding to Guarantee Safety and Coordination?

Efficient communication is crucial for guaranteeing team safety and coordination during scaffolding procedures. Employees can use radios, hand signals, or designated interaction indicate communicate information precisely and immediately across various levels, reducing the danger of accidents.

Verdict

In recap, adherence to ideal safety and security procedures is essential in scaffolding procedures.

Training, inspections, PPE usage, protecting the scaffolding, and adhering to lots limitations are important for preventing accidents and making certain the health of employees.

By focusing on safety measures, the threat of occurrences can be greatly lowered, creating a much safer workplace for all entailed.